WPC board for Cladding

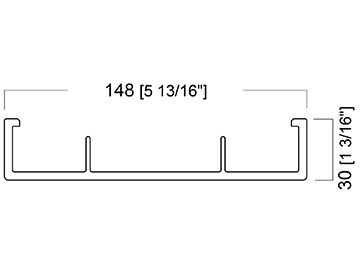

Modulatus TH14830HD-4 for cladding

Board weight Kg/m 0.95 [lb/ft 0.64]

Subframe profiles

Custom lengths

We answer your questions

WPC exterior cladding adds personality and elegance to a building’s aesthetics. Our cladding systems are highly versatile in interpreting various design concepts. Simultaneously, they offer several key technical and functional benefits: enhancing thermal and acoustic insulation, retarding the spread of fire, protecting against weathering (including UV rays, wind, and rain), and resisting mold and pests.

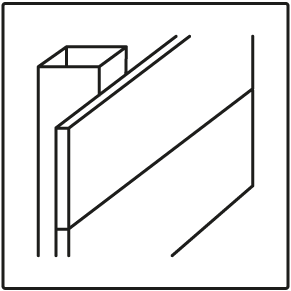

In a ventilated facade system, unlike traditional exterior cladding, panels are mounted on a metal substructure slightly spaced from the walls. This creates a cavity between the wall and cladding, allowing for natural air circulation to enhance the building’s thermal-energy performance while safeguarding it from external moisture and heat. Woodn Greenwood’s substructure systems enable the design of ventilated facades.

Thanks to the protective action of PVC, the use of certified pigments, and brushed or striped matte finishes, the color degradation of UV-exposed boards is minimal upon initial exposure, after which it stabilizes. Specifically, there are no significant changes in shade after 5 years.

Modulatus WPC cladding planks require minimal maintenance. After the first application, cleaning with high-pressure water under 80 bar is sufficient. The aesthetic performance doesn’t fade over time. In any case, a brief maintenance and handling manual for the slats is available in the Technical Area.

WPC is self-extinguishing, fire and weather resistant. The wood-polymer compound does not need protective coating, does not crack or splinter, is woodworm and mildew resistant, and comes in custom lengths.