WPC systems and profiles for fencing, pergolas and special applications

Browse ProjectsWoodn Greenwood boards and profiles offer innovative solutions that go beyond traditional covering and decking designs for use in fencing, pergolas, footbridges and much more. Designers and sculptors have already taken advantage of our materials’ properties to create unique artworks and new artistic explorations

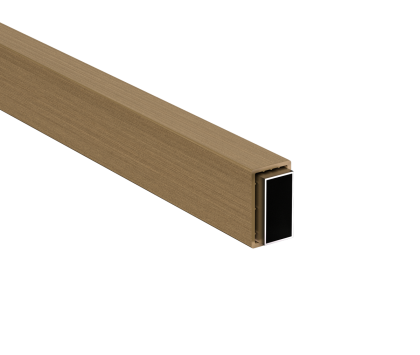

Versatilis Sunshade for pergolas and fences

Seleziona la doga in base alla forma della sezione

Special creations using Woodn Greenwood products

Our collections of profiles and Woodn Greenwood’s end-to-end production offer designers and builders unique customization opportunities.The distinctive properties of our WPC inspire artists and designers to creativity and research.Our technical office offers consulting and assistance services to assess customized designs and new application possibilities.

Sculptures and works of art with thermoformed WPC

Go to the projectDesigner pergolas with Versatilis sunshades

Go to the projectUltra seawater resistant mooring poles

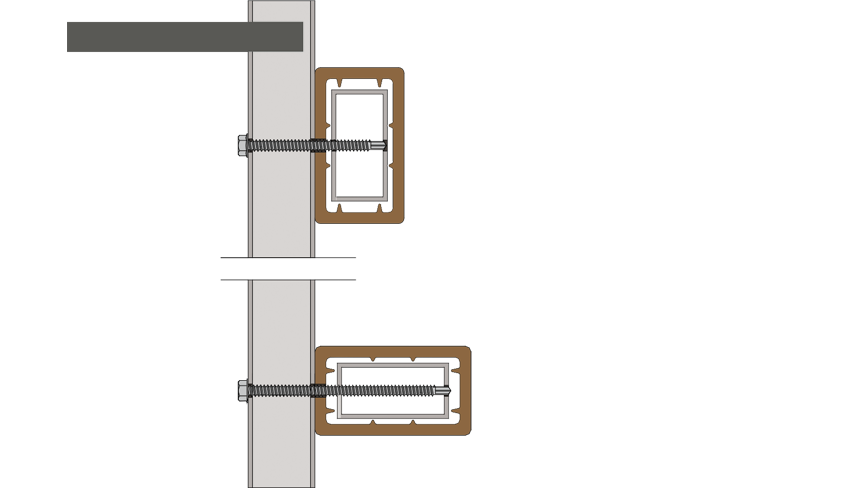

Go to the projectAll Greenwood systems and boards include inserts and metal under-structures, installation accessories and quick-and-easy fastening instructions for a variety of applications.

In the Technical Area, you will find “General Installation Instructions”, “Handling, Cleaning and Maintenance Notes” and CAD blocks for design.

Technical area

Our original WPC woods, unlike other composite woods, allow profiles to be shaped through thermoforming, either in the factory or directly on the construction site. This means that the profiles can also be curved with very tight radii to fit even rather articulated surfaces.WPC WOODN, for example, has been used for years by artist Mirko Demattè to make sculptures and paintings with material inserts.

WPC Laboratory

Finishes

The brushed finish replicates the natural touch & feel of real wood

Brushed surfaces

01 - Avorio

99 - Cuba

01 - Bianco Carrara

10 - Caffè Bogotà

33 - Beige Sahara

02 - Lagorai

13 - Myanmar

14 - Grigio Silverstone

28 - Grigio Londra

48 - Black

77 - Cocowalk

80 - Terracotta

73 - Sinai

smooth surfaces

01 - Bianco Carrara

99 - Cuba

80 - Terracotta

77 - Cocowalk

73 - Sinai

48 - Black

33 - Beige Sahara

28 - Grigio Londra

14 - Grigio Silverstone

13 - Myanmar

10 - Caffè Bogotà

02 - Lagorai

01 - Avorio

FAQs

We answer your questions

Thermoformable means that our WPC material can be shaped by heat. Thermoformable WPC planks can be shaped to fit various surfaces or configurations, offering flexibility in design and installation.

WPC GREENWOOD composite wood was evaluated in the laboratory with the collaboration of the Venice Research Consortium, revealing itself as a “New eco-friendly material for applications on lagoon furniture“. In particular, its physical-mechanical properties were measured: durability, impact resistance and resistance to attack by teredines, organisms responsible for the deterioration of wood immersed in seawater. The result of the tests certifies that WPC GREENWOOD artifacts do not release microplastics, and therefore the material was chosen for the replacement of the historic “bricole” of the Venice Lagoon, with a great savings in terms of maintenance and deforestation.

Versatilis sunshade profiles are extremely eclectic in shape and size. It is up to the designer to select the most suitable slat for a pergola, canopy, fence or parapet.

Our WPC products require minimal maintenance. After the first application, cleaning with high-pressure water under 80 bar is sufficient. The aesthetic performance doesn’t fade over time. In any case, a brief maintenance and handling manual for the slats is available in the Technical Area.

WPC is self-extinguishing, fire and weather resistant. The wood-polymer compound does not need protective coating, does not crack or splinter, is woodworm and mildew resistant, and comes in custom lengths.

Wood Plastic Composite is 100 percent recyclable. It’s made from wood powders which, in the case of Woodn Greenwood products, are FCP® certified. All waste material is transformed by us into new raw material, which we reuse to produce new profiles. In this way, we combat global deforestation. The extrusion process utilizes cooling water with a recirculation system. For more in-depth information, we recommend visiting the Green Vision page of this website.