Born in Venice

Woodn Greenwood is a full-service company that formulates original and sustainable WPC "raw materials" in its internal laboratory, composed by a mixture of wood fibers and exclusive polymers which, through the extrusion technique, are transformed into finished profiles and systems.

The company, which started its business in 2002, is based in Belluno, in the heart of the Dolomites; the production - a factory, with 9 extrusion lines, inaugurated in 2021 - and warehouses are located in Treviso where commitment, creative approach and know-how come together for a winning combination, fully expressing ingenuity and creativity which are a characteristic expression of Made in Italy.

Our industrial technique gets inspiration from the Venetian manufacturing tradition, made up of ingenuity, rigor and craftsmanship. The materials, born from careful Research and Development, are eco-sustainable, durable, recyclable, and designed to overcome the limits of traditional wood while maintaining its appearance.

Thanks to this approach, Woodn Greenwood's WPC products from Venice have quickly gained recognition among leading architectural firms worldwide, expanding design possibilities and paving the way for new, exciting explorations.

The Company, thanks to its internal design capacity, is always at the architect's side, to model and materialize the design concepts, help him choose the most suitable system and satisfy the most diverse needs of any architectural intent.

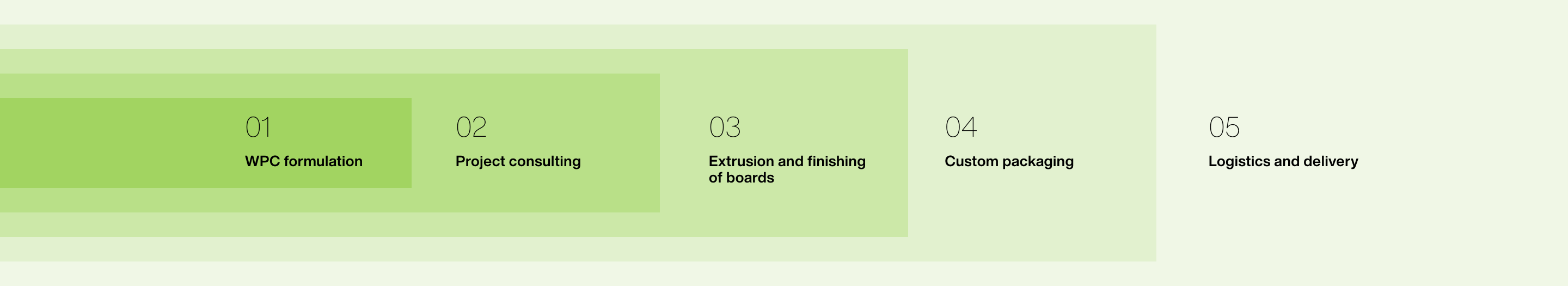

OUR PRODUCTION PROCESS

Services in design phase

We support architects, builders and contractors in the evaluation of the application systems, in the preliminary quantification of the supply and in the development of customized solutions for every project need.

DESIGN SUPPORT: we identify and quantify the scope of work, implementing the technical and aesthetic proposals in order to meet the design intent along with the support of technical documentation. All typical technical details, developed through the years, help the designer to select the most appropriate system.

SAMPLES AND MOCKUPS: an ad hoc internal department prepares and packages samples and mock-ups for designers, installers or customers in order to provide a 1:1 scale and realistic representation of the job.

SHOP DRAWINGS: an internal team of engineers and architects uses BlueBeam and Autocad 2d and 3d to provide executive details of the applications present in the project, adapting them to the construction site conditions.

PROJECT MANAGEMENT: from the approval of the shop drawings, through production scheduling, packaging, up to delivery to the construction site, the company monitors all phases of the supply to deliver the materials on time in Italy and overseas, meeting sites’ deadlines.

Services port delivery

Once the material is delivered to the construction site, Woodn Greenwood's service continues.

The internal technicians continue to support the installer by giving advice through cutting lists, packing lists and installation drawings.

We know well how much the success of a construction site depends on the perfect execution of the work and we support the installer during the phases of recognition of the profiles, accessories, the explanation of the technical sheets and the recognition in the executive drawings of all the details that resolves the expected and unexpected critical issues of the construction site.

TRAINING PROGRAM

Woodn Greenwood in an official provider of the American Institute of Architects for consulting and training for architects and builders in the United States as well.

COMPANY CERTIFICATIONS

Operating in an international context, Woodn Greenwood is an ISO 9001 certified company, issued by IMQ (Italian Quality Mark Institute), a global recognition that certifies the effectiveness of the management systems for the quality of its organization’s processes.

By offering the construction sector an alternative material to natural wood, the company stands out on the international scene for having achieved the FSC® certification. This certification proves the commitment to use wood coming from responsibly managed forests, ensuring that satisfying today's needs will not compromise tomorrow’s world.

All Woodn Greenwood products can contribute to LEED® credits according to the LEED® BD+C V4 protocol. The LEED® rating system certifies the building and provides the market with a shared approach on which to base the choices and a measurable standard for each aspect. Woodn Greenwood's report shows the company's excellence in relation to LEED® credits.

ISO9001 Certification | LEED® Mapping | FSC® Certification