WPC systems for ceilings and soffits

Browse ProjectsModulatus ceiling and soffit systems for various applications improving thermal and acoustic insulation, with NRC coefficient of sound absorption up to 0.85.

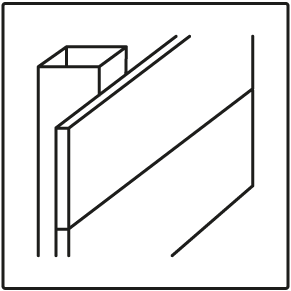

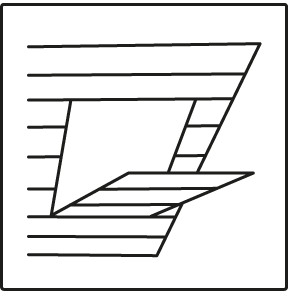

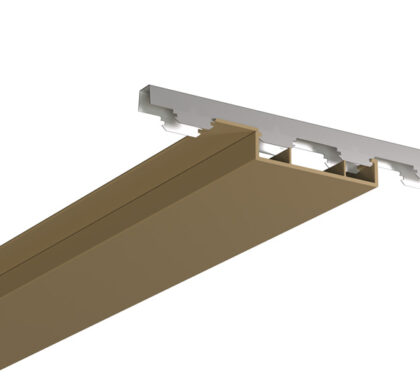

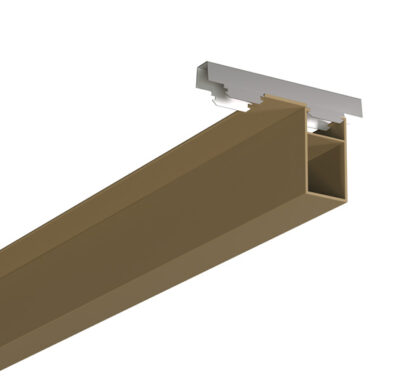

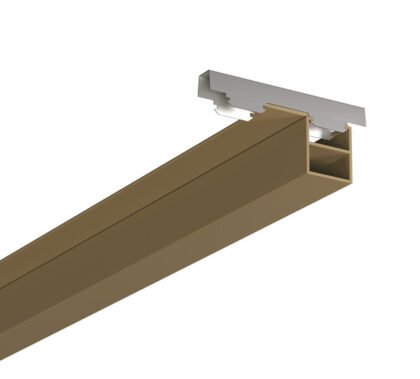

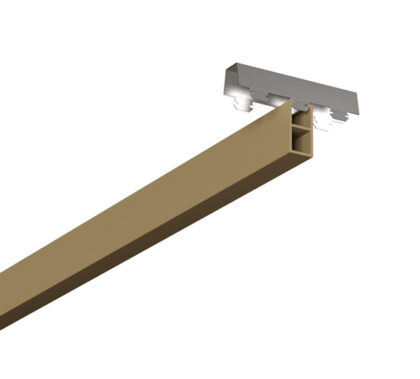

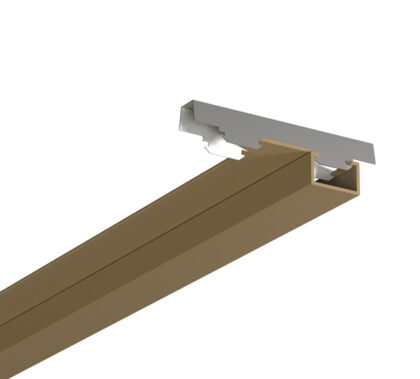

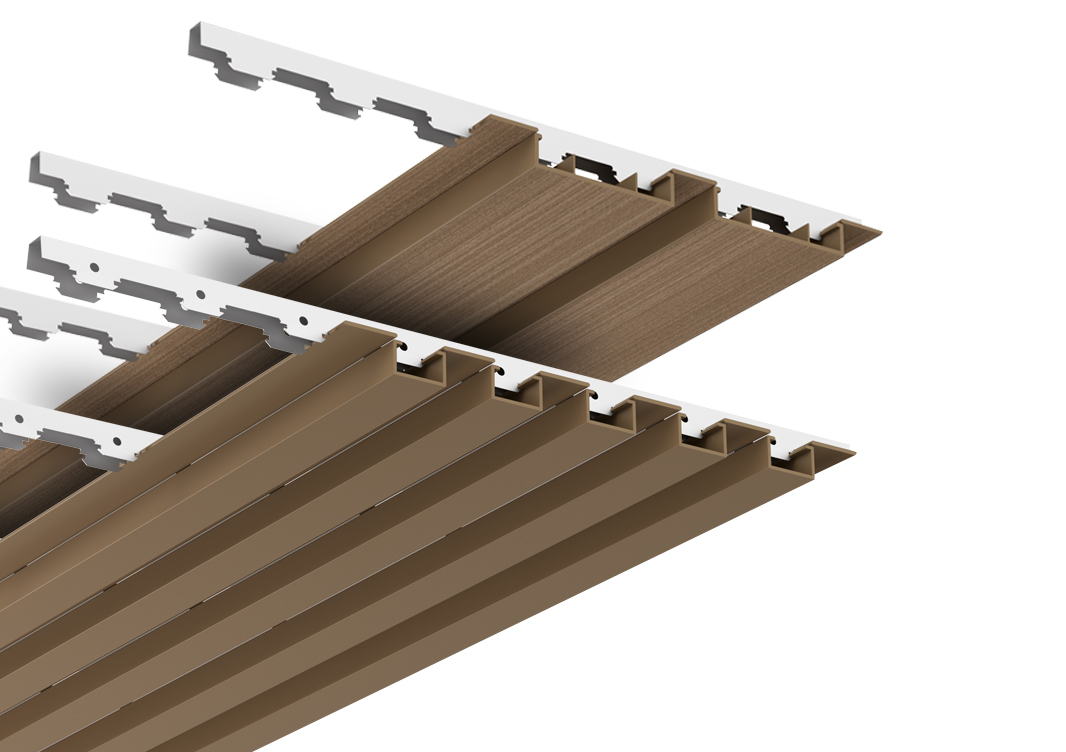

5 ceiling and soffit systems, each of which allows at least 2 different configurations. The versatility and the wide range of colors, together with the finishing accessories in the same material, allow to solve and satisfy any technical and aesthetics requirement. The profiles have dimensions ranging from 50 to 148 mm (2” to 5” ¾ ), can be installed next to each other or spaced apart. It is possible to create inspection panels or install lighting, sprinklers and air conditioning systems.

Modulus false ceiling systems

Ceiling and soffit creations using Modulatus systems

Modulatus WPC false ceilings and soffits are available with the same finishes and color ranges as vertical cladding coverings and sunshade profiles for esthetic continuity between façades or walls, sunshades and false ceilings.

Outdoor ceilings for acoustic and thermal insulation

Go to the projectIndoor suspended ceilings with integrated lighting

Go to the projectCeiling systems finished and coordinated in every detail

Go to the projectCeiling and soffit systems include subframe profiles, can be produced in custom length can be integrated with lighting or springlers systems and fabricated to create inspection panel.

In the Technical Area, you will find “General Installation Instructions”, “Handling, Cleaning and Maintenance Notes” and CAD blocks for design.

Technical area

All ceiling and soffit profiles are made of WOODN WPC composite wood.

The PVC polymeric component protects against weather and temperature changes at any latitude and altitude. The wood component and the extrusion technique provide a perfect esthetic finish for the false ceiling, with better colorfastness and architectural stability than natural wood.

WPC Laboratory

Finishes

The brushed finish replicates the natural touch & feel of real wood

Brushed Surfaces

80 - Terracotta

73 - Sinai

48 - Black

77 - Cocowalk

14 - Grigio Silverstone

28 - grigio Londra

13 - Myanmar

02 - Lagorai

33 - Beige Sahara

10 - Caffè Bogotà

01 - Bianco Carrara

99 - Cuba

01 - Avorio

Smooth Surfaces

01 - Bianco Carrara

99 - Cuba

80 - Terracotta

77 - Cocowalk

73 - Sinai

48 - Black

33 - Beige Sahara

28 - Grigio Londra

14 - Grigio Silverstone

13 - Myanmar

10 - Caffè Bogotà

02 - Lagorai

01 - Avorio

FAQs

We answer your questions

A WPC drop ceiling enhances thermal and acoustic insulation in a room by creating an air chamber between surfaces. Additionally, it fulfills various aesthetic requirements: it can conceal electrical wiring or ductwork, serve as a support structure for decorative light fixtures, or conceal old and damaged ceilings.

While there are no limits for an outdoor suspended ceiling, the minimum height of an indoor drop ceiling is typically regulated by national or local building codes. As these regulations vary by location, we encourage designers to consult them before finalizing the design.

Thanks to the protective action of PVC, the use of certified pigments, and brushed or striped matte finishes, the color degradation of UV-exposed profiles is minimal upon initial exposure, after which it stabilizes. Specifically, there are no significant changes in shade after 5 years.

Modulatus WPC ceiling profiles require minimal maintenance. After the first application, cleaning with high-pressure water under 80 bar is sufficient. The aesthetic performance doesn’t fade over time. In any case, a brief maintenance and handling manual for the slats is available in the Technical Area.

WPC is self-extinguishing, fire and weather resistant. The wood-polymer compound does not need protective coating, does not crack or splinter, is woodworm and mildew resistant, and comes in custom lengths.

Wood Plastic Composite is 100 percent recyclable. It’s made from wood powders which, in the case of Woodn Greenwood products, are FCP®-certified. All waste material is transformed by us into new raw material, which we reuse to produce new profiles. In this way, we combat global deforestation. The extrusion process utilizes cooling water with a recirculation system. For more in-depth information, we recommend visiting the Green Vision page of this website.

You may also be interested in other products